Every package company and market are different. This is reflected by the various layouts of depots and sortation centers. Our experts are available to offer help and advice in every respect.

Infeed

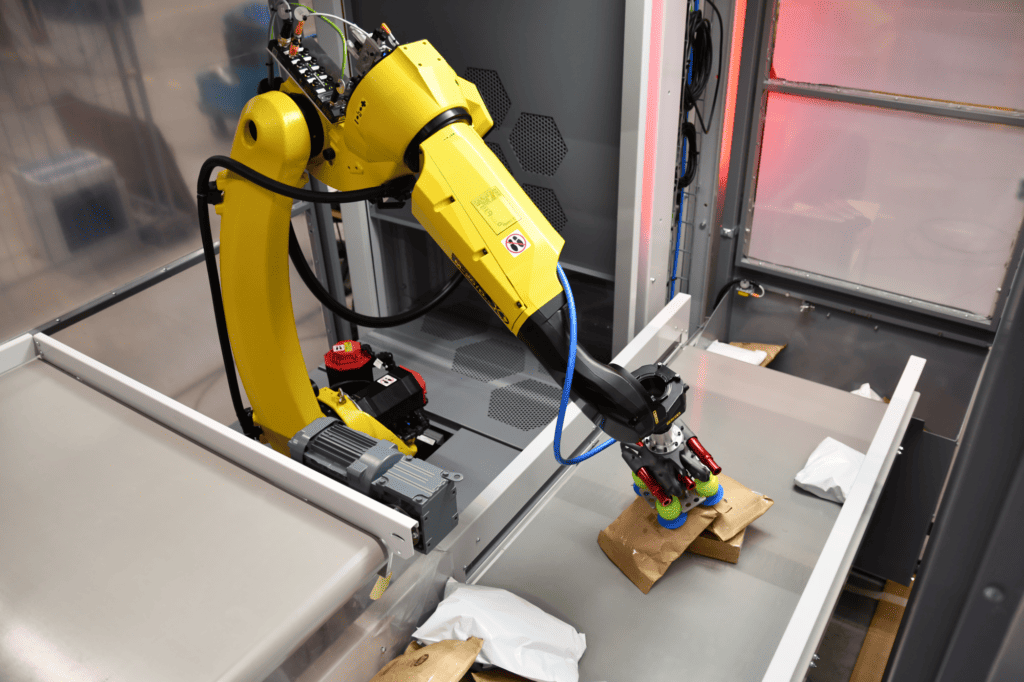

Several infeed points are required in busy parcel hubs. These are where varying sizes of parcels are fed onto the sorter before the final sortation and shipping processes can take place.

Continue reading