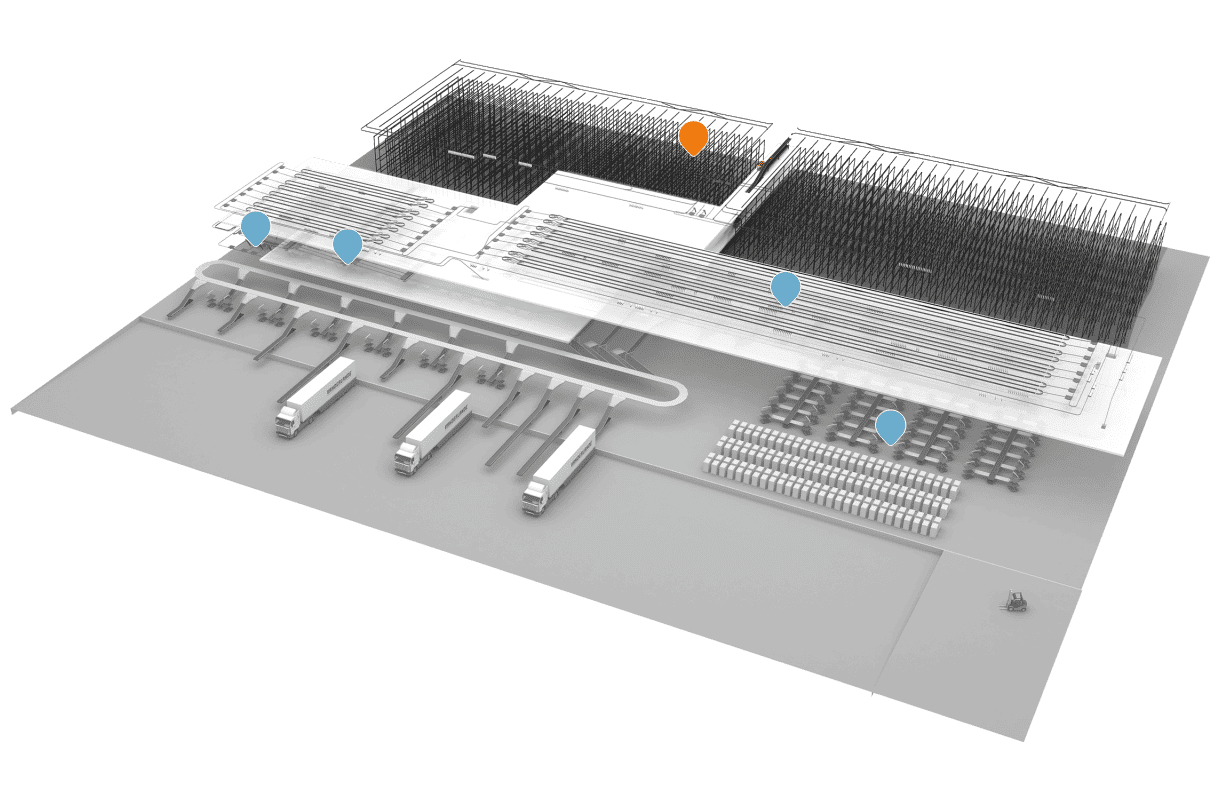

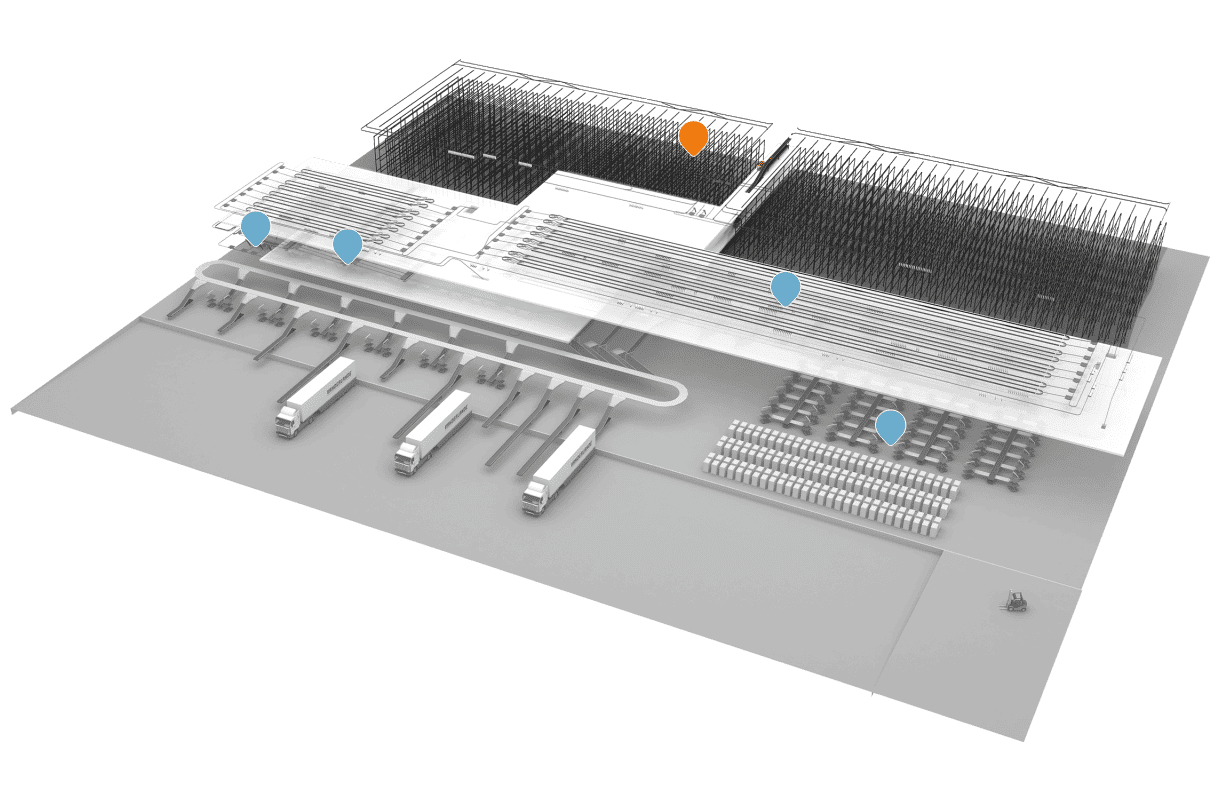

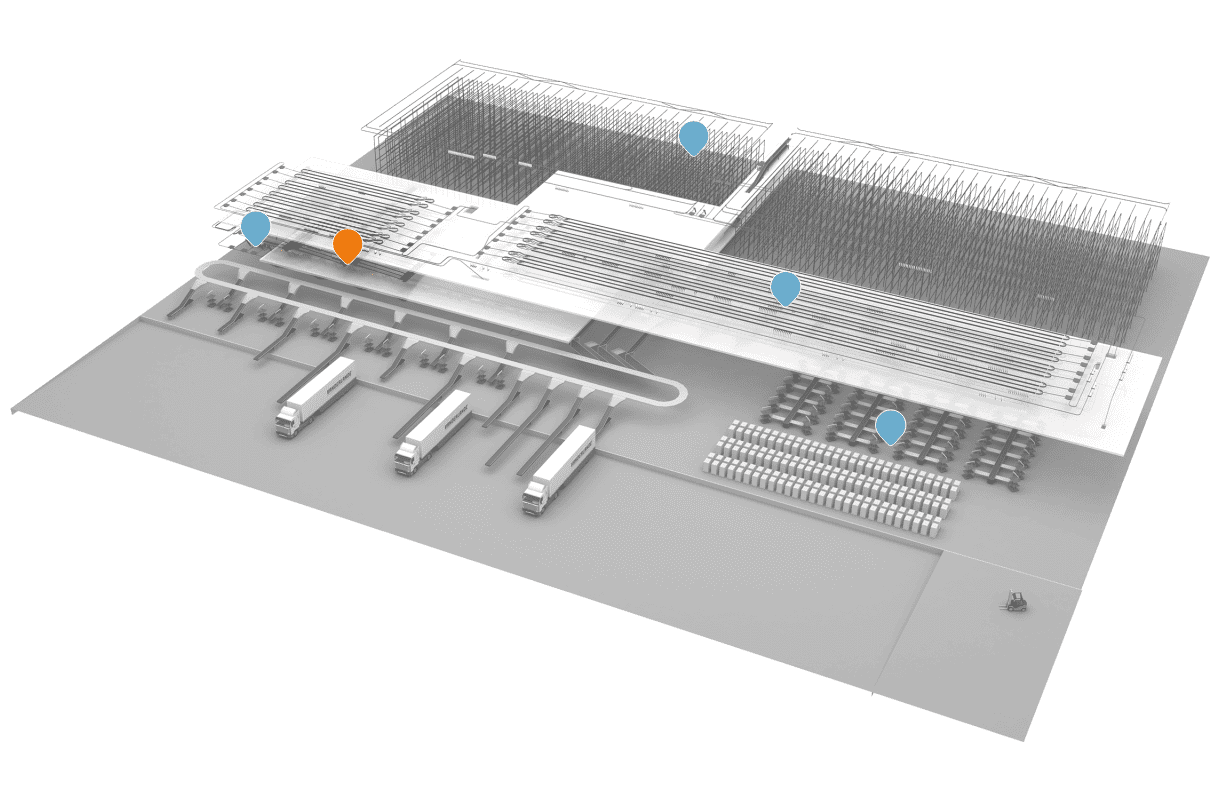

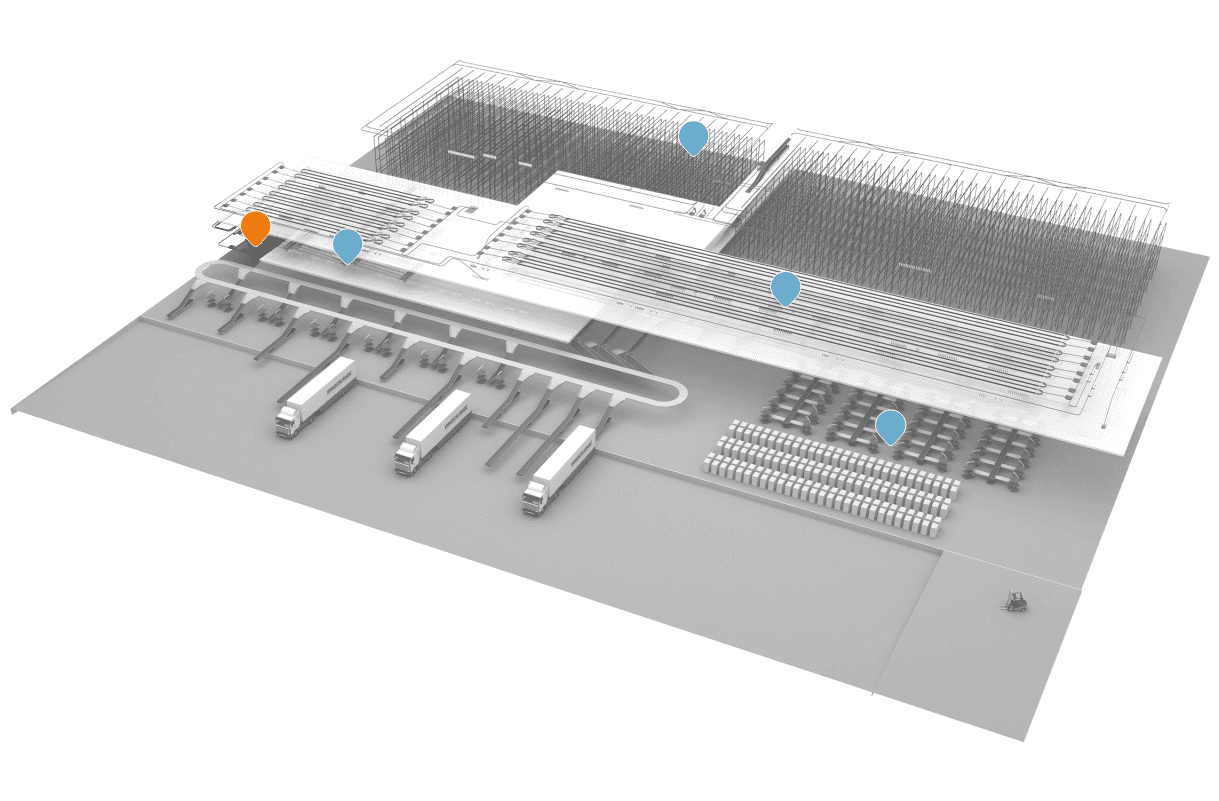

Every company and every market is different. This is reflected in the layout of your warehouse – and the advice offered by our experts.

Picking

Items are picked manually from various warehouse areas in a continuous flow.

Home » Warehousing » Solutions » AIRPICK

E-commerce and omnichannel warehouses and distribution centers (DCs) are challenged to fulfil thousands of orders with ever-increasing service level requirements. However, it is difficult to accommodate time-critical processes in a DC that may not be optimized to meet these requirements. Unpredictable demand and seasonal trends call for flexibility. Warehouses and DCs must cope with the changing – and increasing – variety of stored products and order volumes. They also need to efficiently handle the expanding number of returns.

As part of our next generation of scalable solutions – evolutions – Vanderlande offers AIRPICK, which seamlessly integrates innovative systems, intelligent software and life-cycle services.

AIRPICK is an order fulfilment solution for General Merchandise, and Fashion, pure e-commerce and omnichannel companies designed to maximize the picking efficiency of a solution based on manual item picking.

The core of this solution is Vanderlande’s AIRTRAX pocket sorter system to sort large efficient batches of items to individual orders. This system ensures a smooth and efficient order fulfilment process and enables an efficient handling of returned items, regardless of the product (boxes, apparel, hanging goods), order size and is scalable with the required throughput.

AIRPICK offers:

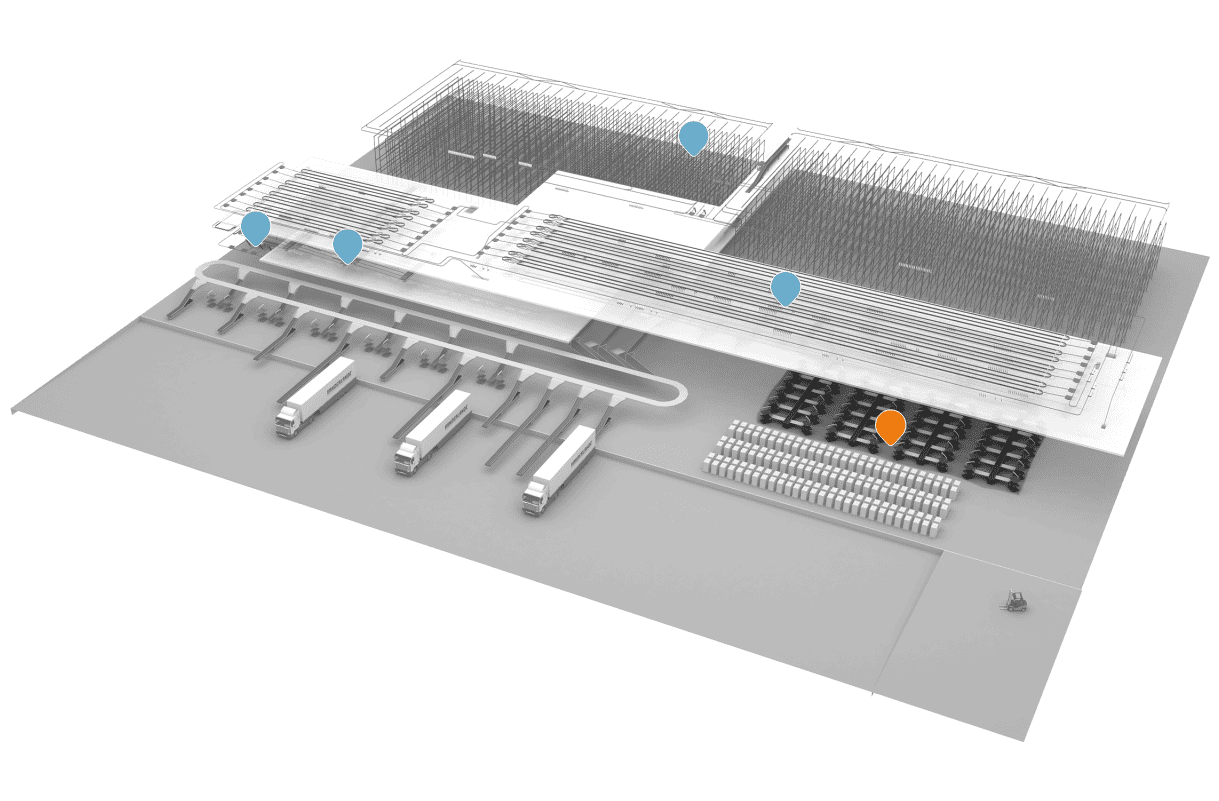

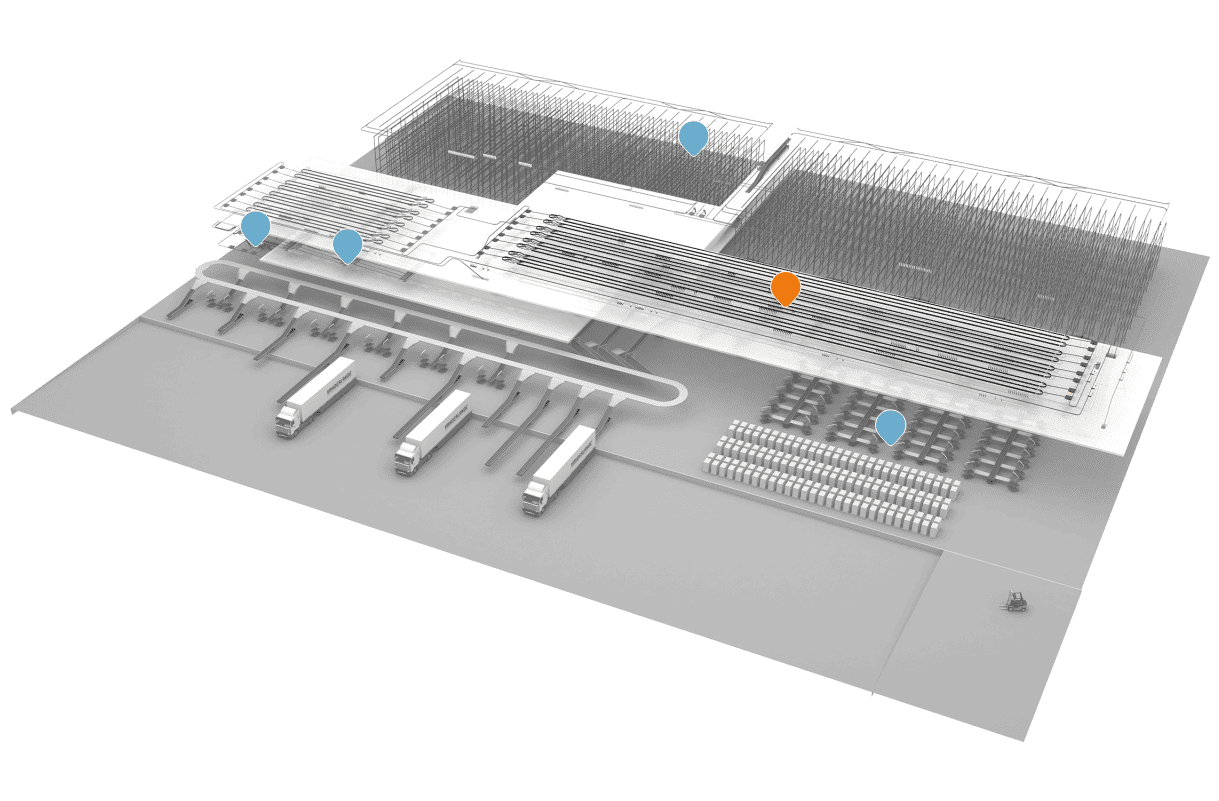

Items are picked manually from various warehouse areas in a continuous flow.

Each pocket is randomly inducted with one item. This can also be done with a smart item robot (optional).

Items are sent into and retrieved from dynamic buffer loops. This also allows for fully automated handling of returned items.

Items are automatically sorted to individual orders and moved in the desired sequence.

Items are presented to the pack operator per order and, if required, in the desired sequence.

AIRTRAX is our innovative and reliable family of products for transporting, sorting, sequencing and storing hanging goods.

Continue readingVISION is our next generation of software that intelligently connects and orchestrates your system’s equipment, robotics, people and processes. It’s our single platform for all automated and manual warehouse functions.

Continue readingOur Smart Item Robotics (SIR) consists of a portfolio of intelligent, self-learning and extremely flexible picking robots. Our robots – such as the item pick-and-place variant – will become a seamless part of your logistic process and work side by side with our automated storage and retrieval solutions (AS/RS).

Continue readingEvery company and every market is different. This is reflected in the layout of your warehouse – and the advice offered by our experts.