STOREPICK

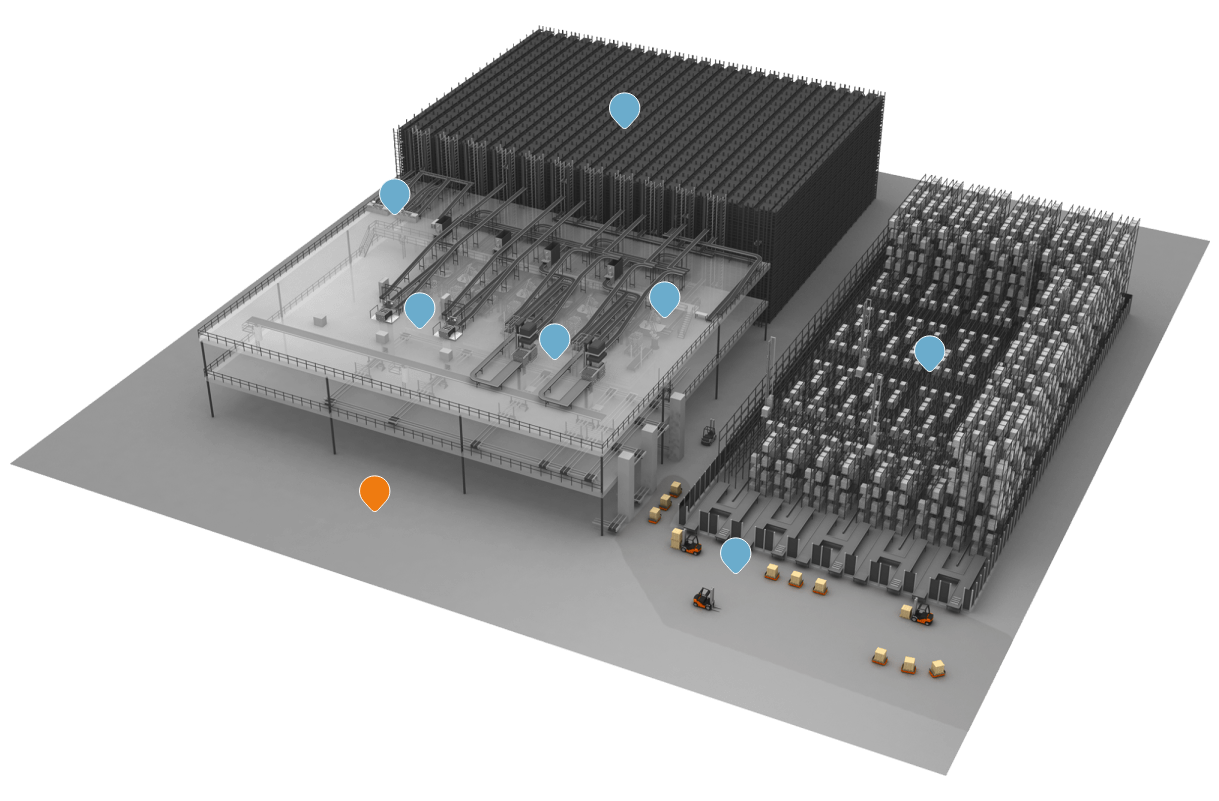

In today’s food retail market, many companies are challenged by a lack of available workforce at their distribution centers. This means that the automation of core warehouse processes is crucial to ensure ongoing success.

In addition, the growing number of multiple store formats is making store-friendly deliveries increasingly important. This includes both full case – and single item – deliveries. The expand-ing number of SKUs (stock keeping units) also has an impact on effective space use.

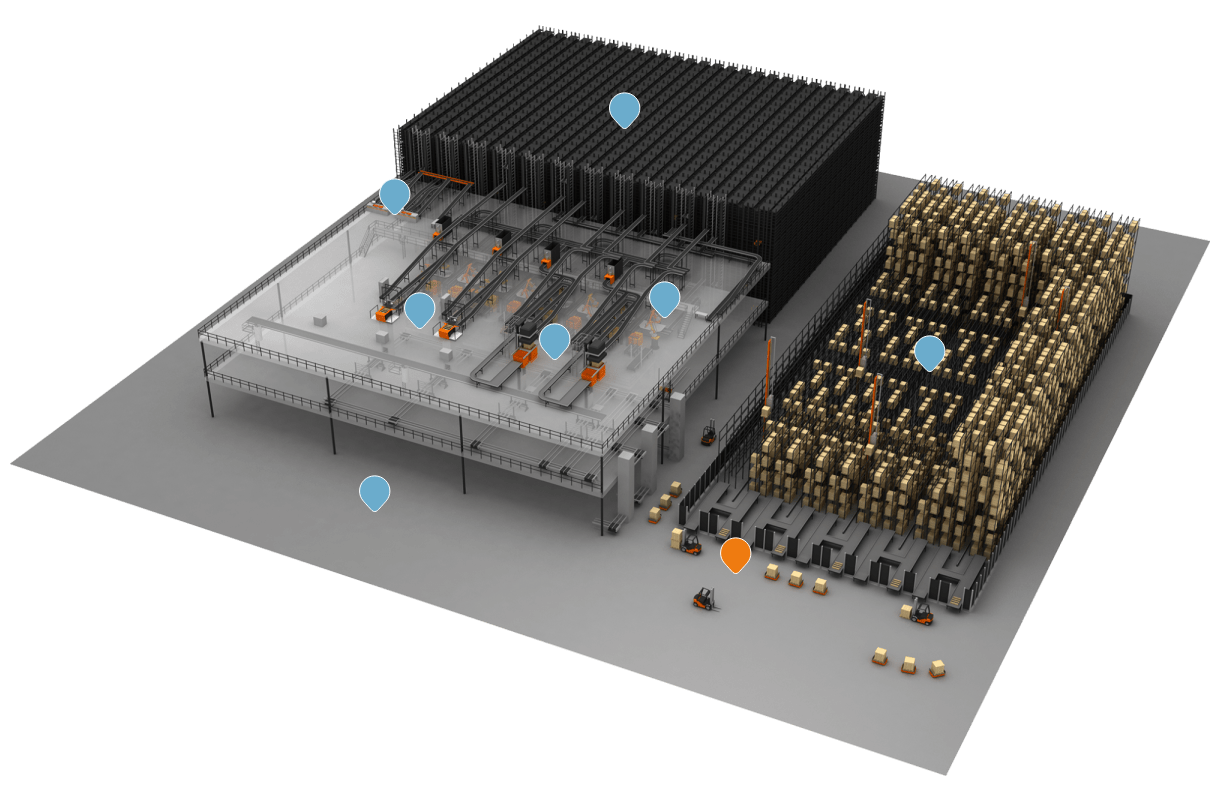

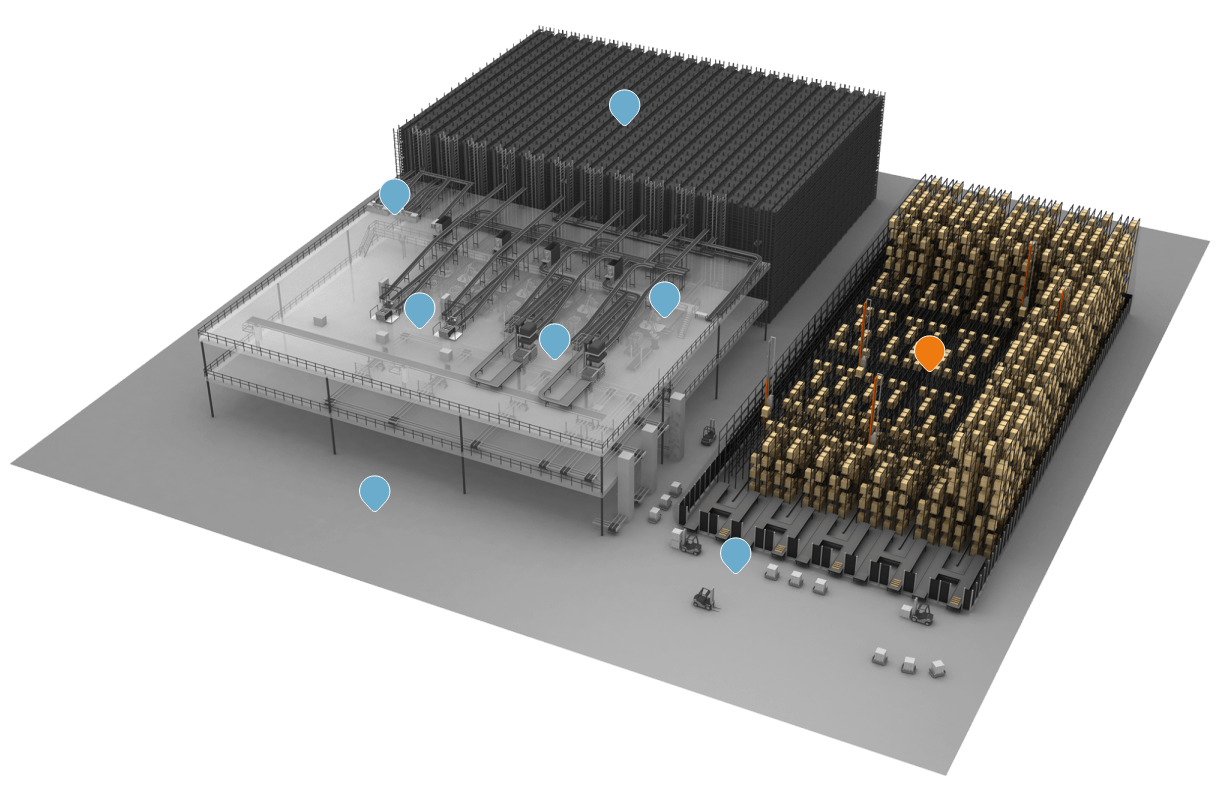

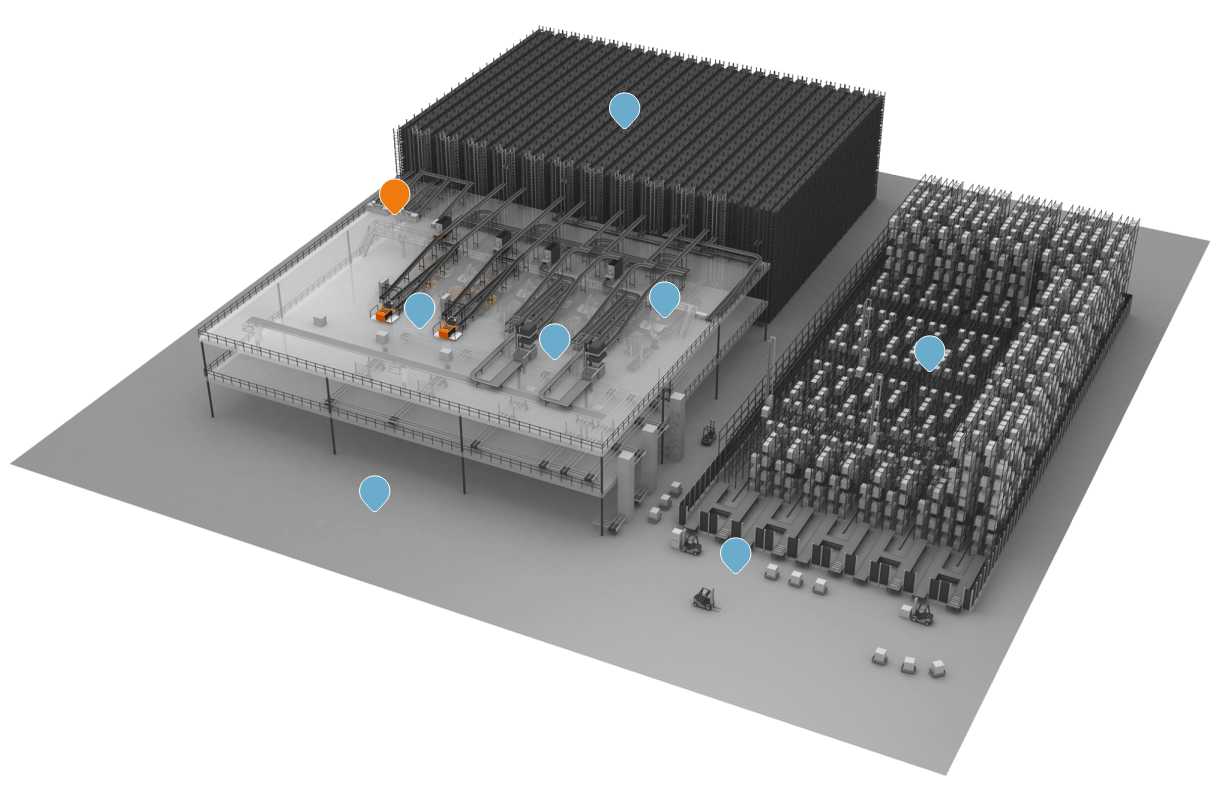

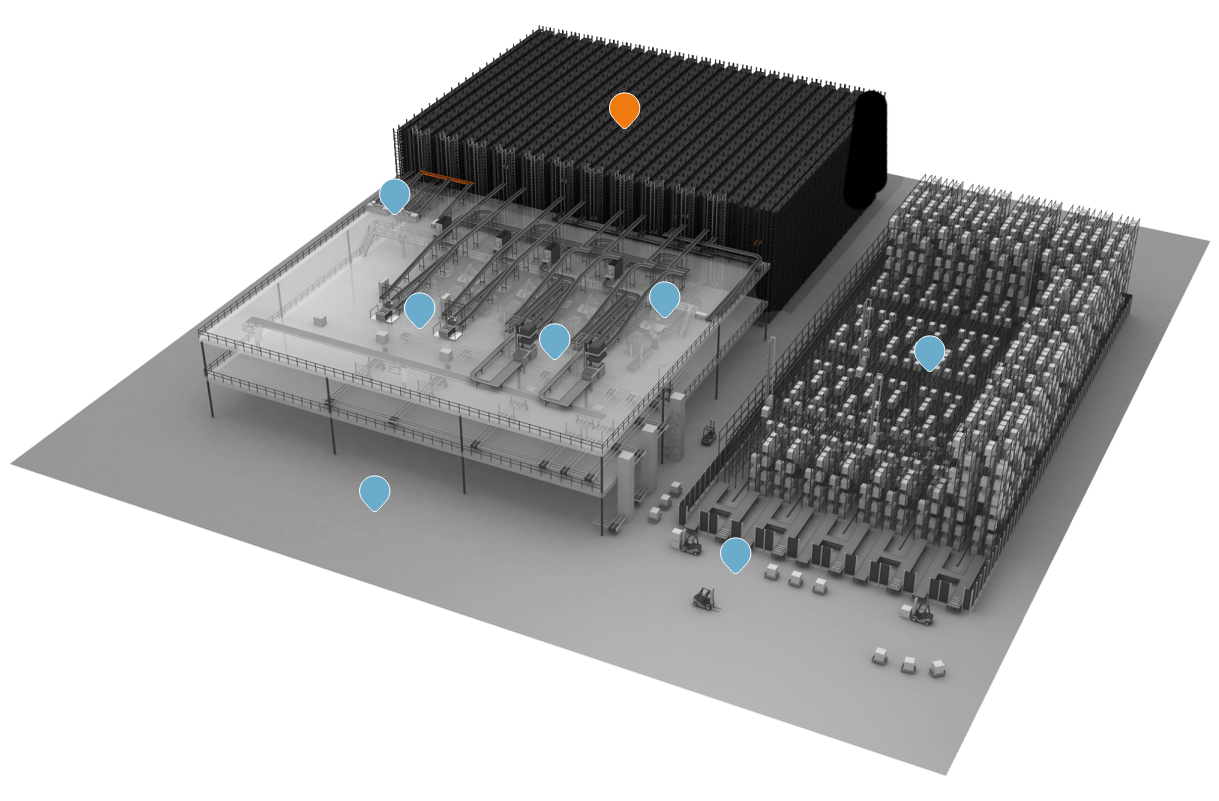

To keep up with an exponentially growing market, scalable solutions are vital. As part of our next generation of scalable solutions – evolutions – Vanderlande offers STOREPICK, which seamlessly integrates innovative systems, intelligent software and life-cycle services.

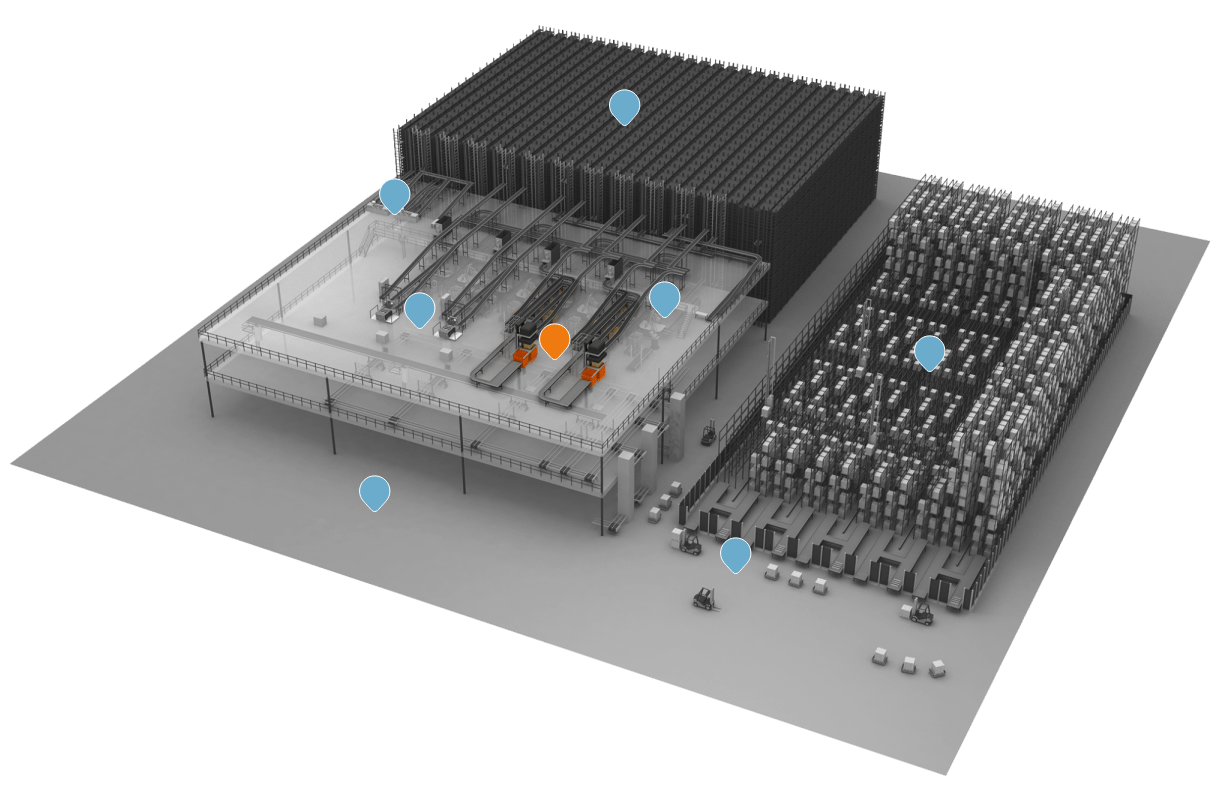

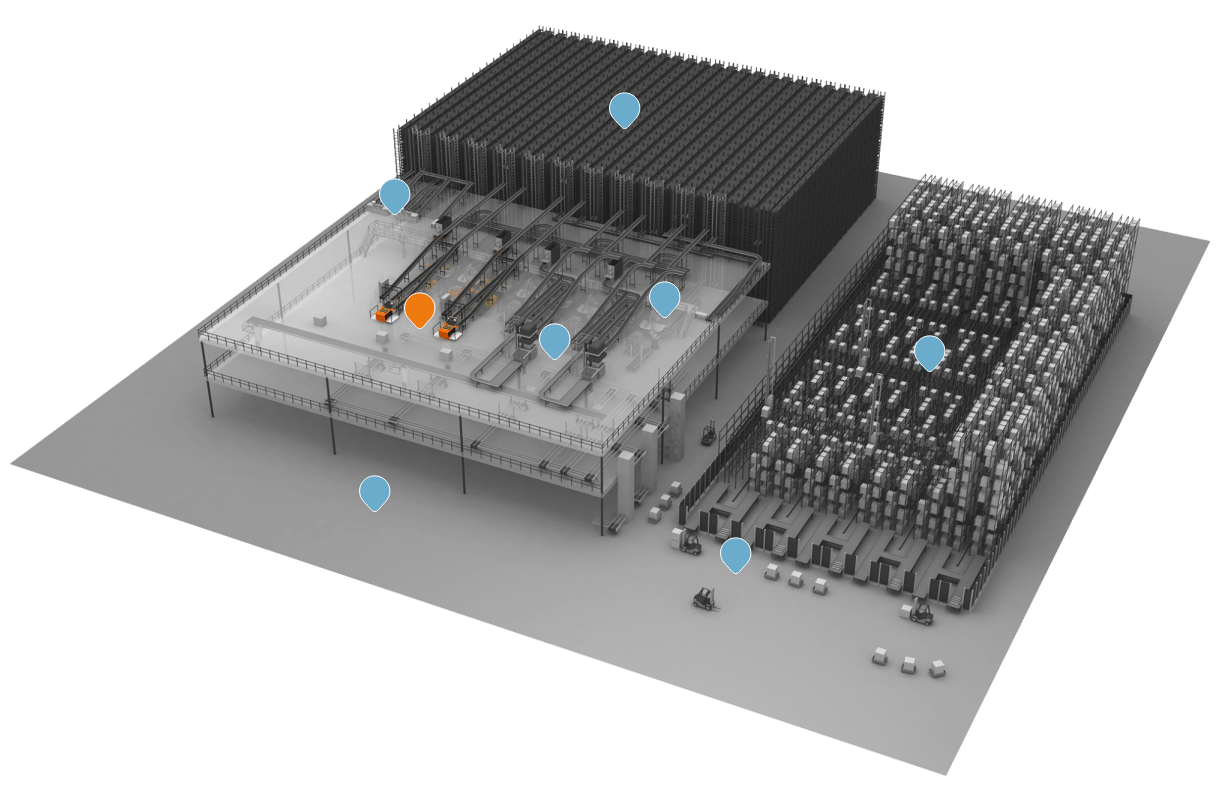

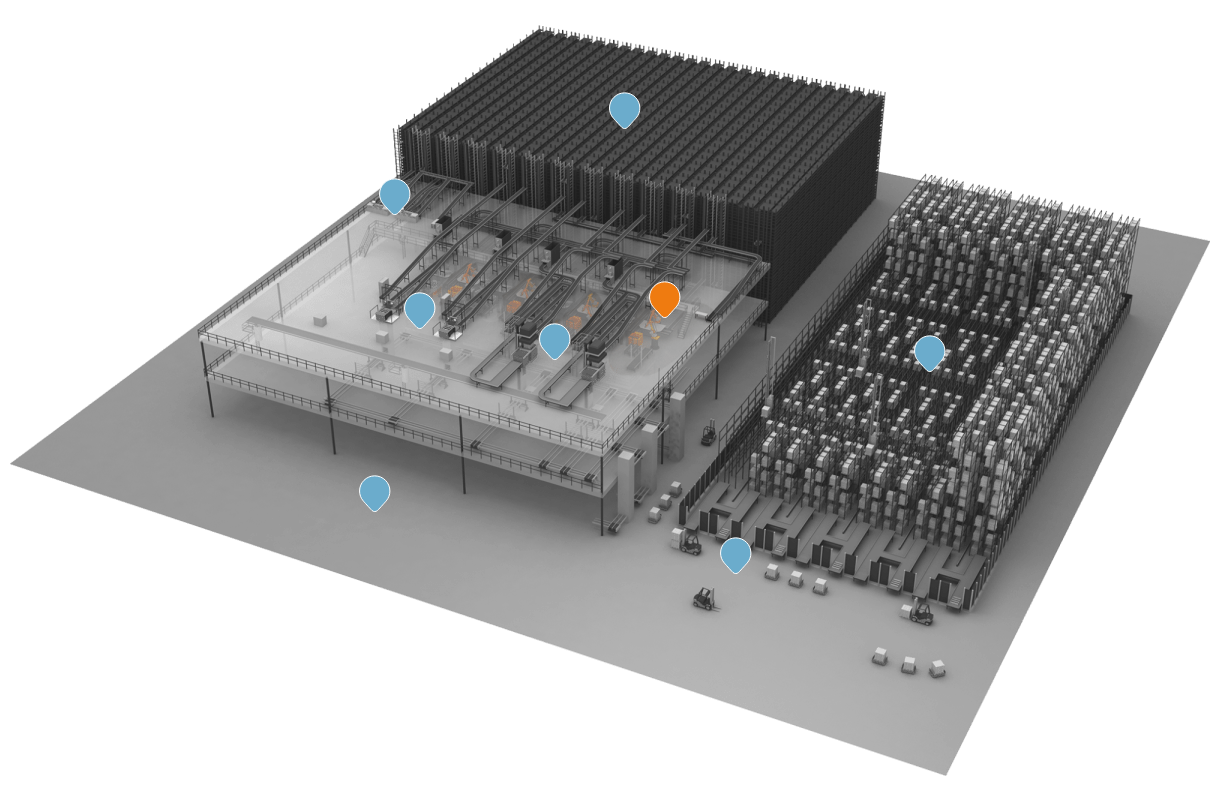

STOREPICK is a robotized, end-to-end automated case picking (ACP) solution designed for re-tail distribution that allows you to optimize the processes of your entire supply chain. STORE-PICK utilizes a modular design to prevent single points of failure and allow for flexibility and future expansion. Vanderlande’s proven Load Forming Logic (LFL) guarantees store-friendly deliveries across multiple store formats.

STOREPICK is ideal for retailers that use ambient, fresh and chilled warehouse processes, and offers:

- store-friendly deliveries

- the efficient transport of products

- a redundant design